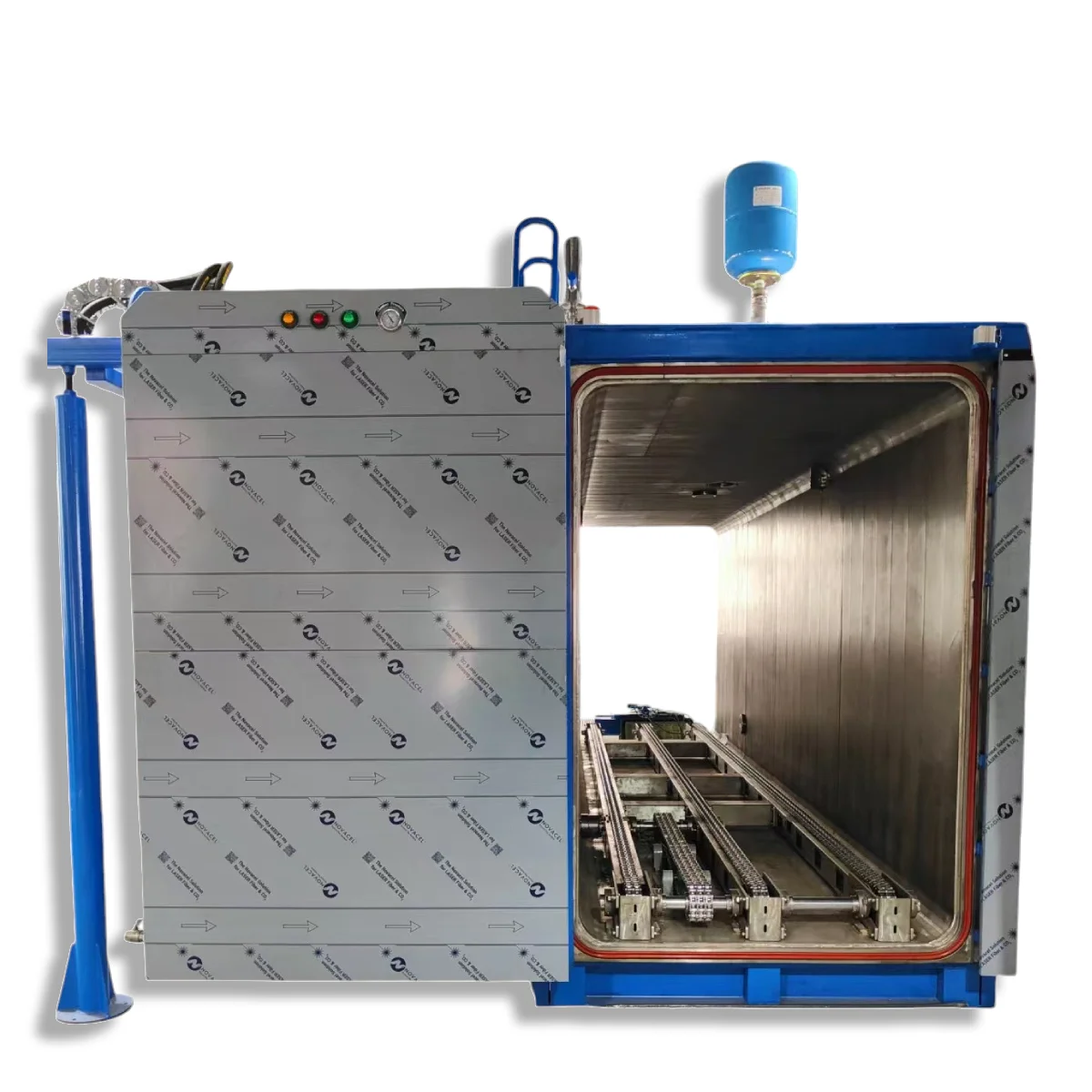

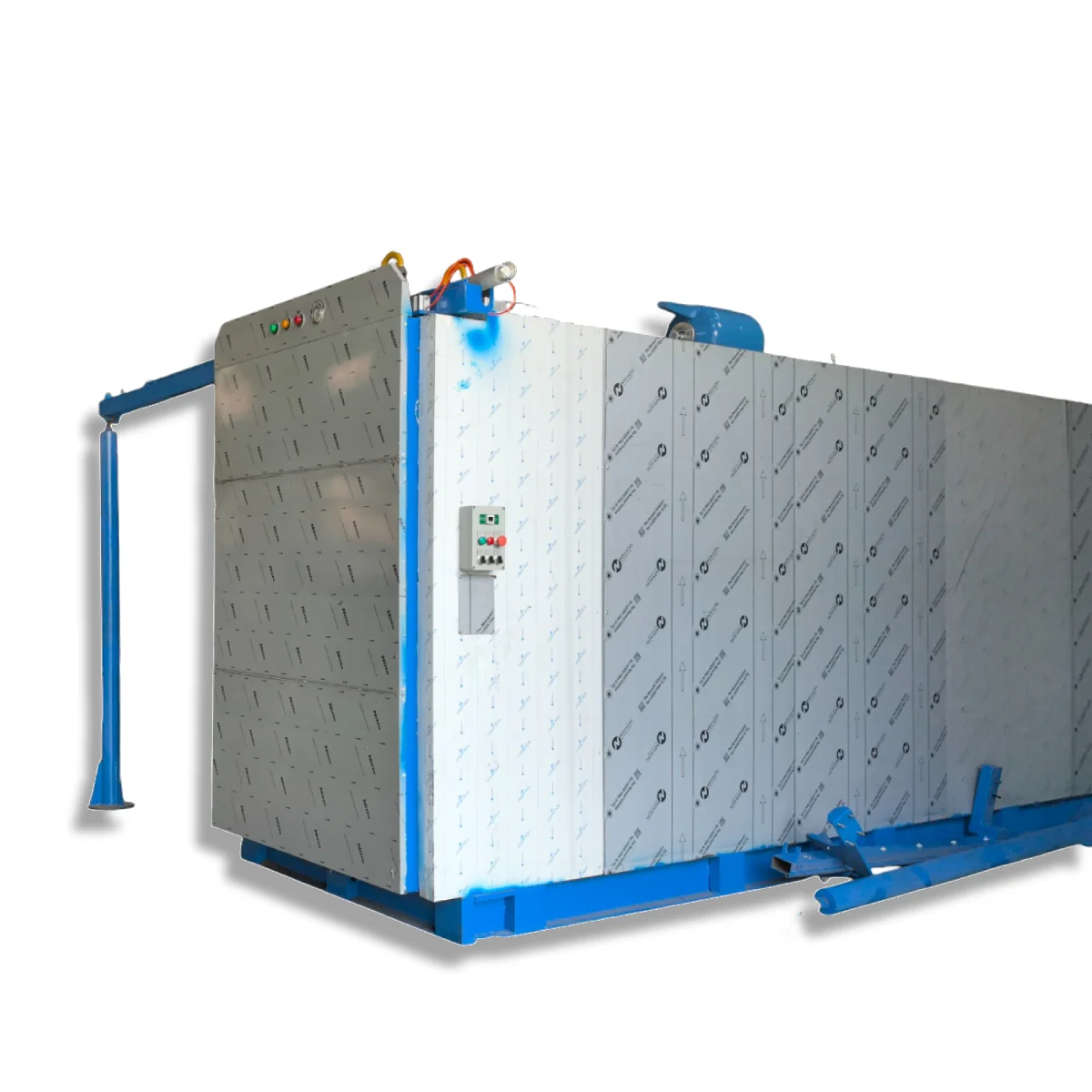

Industry ethylene oxide gas sterilizer Turnkey EO Sterilization Project

A turnkey project is a complete project that is designed, built, and tested by a single provider. In the context of ETO sterilization, a turnkey project typically involves designing and building a complete ETO sterilization facility, including :

* preheating room

* Aeration Room

* Scrubber

* Sterilization conveyor system

* control system cabinet

* local control box

* etc

Why Ethylene Oxide Sterilization? Key Advantages

ethylene oxide gas sterilizer are the gold standard for materials that cannot withstand high heat or radiation. Here’s why industries rely on them:

- Broad Material Compatibility

EO effectively sterilizes plastics, rubber, electronics, and multi-layer packaging without compromising structural integrity. - Deep Penetration Power

Reaches intricate geometries (e.g., catheters, endoscopes) and porous materials that steam or UV light cannot. - Low-Temperature Process

Operates at 37°C–63°C, ideal for heat-sensitive medical devices and lab equipment. - Regulatory Compliance

Meets ISO 11135, FDA, and EU MDR standards for medical device sterilization.

How EO Gas Sterilization Works: A 4-Step Process

Modern EO sterilizers, like those from ZJBOON, automate critical phases to ensure safety and efficiency:

- Preconditioning

Adjusts humidity (40%–80%) and temperature to optimize gas diffusion. - Gas Injection

EO concentration is precisely controlled in a sealed chamber. - Exposure Phase

Maintains optimal conditions for 1–6 hours to eliminate bacteria, viruses, and spores. - Aeration & Residual Removal

Advanced vacuum cycles and catalytic converters reduce EO residues to <1 ppm, complying with OSHA and EPA limits.

Applications Across Industries

- Medical Device Manufacturing

Sterilize surgical kits, implants, and syringes without thermal degradation. - Pharmaceuticals

Ensure sterility in drug packaging and biotech equipment. - Aerospace & Electronics

Decontaminate sensitive components prone to moisture damage. - Food Packaging (Non-EU Markets)

Treat spices and herbs in regions where EO is approved (e.g., USA, Asia).

Safety First: Mitigating EO Risks with Technology

While EO is a known carcinogen, next-gen sterilizers integrate safeguards to protect workers and end-users:

- AI-Powered Leak Detection: Real-time sensors monitor chamber integrity.

- Closed-Loop Catalytic Abatement: Converts residual EO into CO₂ and water, achieving >99.9% destruction efficiency.

- Automated Ventilation: Post-sterilization aeration cycles ensure products meet ISO 10993-7 residue limits (<4 μg/cm²).

ZJBOON’s systems exceed OSHA’s permissible exposure limit (PEL) of 1 ppm over 8 hours, aligning with global occupational safety standards.

Choosing the Right ethylene oxide gas sterilizer: 5 Critical Factors

- Chamber Size

Opt for scalable solutions (1–100 m³) to handle bulk loads or niche applications. - Customization

Prioritize suppliers offering tailored cycles for unique materials or throughput needs. - Certifications

Verify ISO 13485 (medical devices) and EPA compliance for environmental safety. - Energy Efficiency

Look for systems with heat recovery and low gas consumption to cut operational costs. - After-Sales Support

Ensure access to calibration, validation, and emergency repair services.

Future Trends in EO Sterilization

- Smart IoT Integration: Remote monitoring and predictive maintenance via cloud platforms.

- Green EO Alternatives: Research into hybrid systems using ozone or nitrogen dioxide for reduced environmental impact.

- Single-Use Device Compatibility: Compact sterilizers for disposable medical products.

Why Partner with ZJBOON?

As a leader in industrial sterilization, ZJBOON delivers:

- 30+ Years of Expertise: CE, and ISO-certified EO sterilizers.

- Turnkey Solutions: Custom chambers, validation support, and global logistics.

- Eco-Friendly Design: Catalytic abatement systems and energy-saving modes.

Reviews

There are no reviews yet.